Our mining operations experience is in our DNA.

For over 30 years, IE has been the provider of choice for mining power distribution solutions. See how our team’s deep experience as mine operators helps us function more as a partner rather than a vendor. Mining is in our DNA.

IE – Engineered by Operators.™

Power Centers / MLCs

Our load centers, built with IE high efficiency dry-type transformers, form the backbone of any underground mine. Standard designs available, or we will work to customize to your specific requirements. Our SmartCenter™ technology integrates key components into a single digital platform and represents the future of underground mining productivity.

- Ruggedized mechanical design; low profile options available

- Standard designs or fully customizable

- Both step-up and step-down transformers available

- Dual primary and secondary voltages available

- Fully manual, or digital / automated (PLC/SmartCenter™) concepts available

- Draw-out component technology available

- Sizes up to 5,000 MVA available

- Voltages up to 25 kV

- Secondary bus for up to 3000A

Specialty Underground

Power Distribution

IE has a full offering of underground specialty equipment – including underground substations, belt and fan controllers and VFDs, distribution boxes, portable gensets, capacitor banks, and other offerings.

- Ruggedized packages for motor controls (MCCs, VFDs, starters, soft-starts), capacitor banks, mobile generators, and other electrical equipment

- Built-in monitoring and automation

- Passive and active cooling packages available for dusty environments

- Automation available for specialty requirements such as load sharing

- LV (<1000V) and MV options available

- See our Underground page for information specific to each type of equipment

Longwall Electrics

IE has provided the longwall electrics on the five highest productivity coal faces in the US. Our designs incorporate the latest power and communications technology available, and you can rest easy as IE works through all MSHA RAMPs / certifications.

- Ruggedized, mobile designs

- Mule train and mono-rail system designs available

- Latest in component technology, communications, and automation for maximum asset productivity

- Work with MSHA to achieve all required approvals

- Up to 10 MVA

- Starter cars with 5 kV feeders

- MSHA approvals

MV Switchgear

Our MV custom switchgear portfolio includes both MSHA compliant underground switchgear as well as traditional UL metal-clad switchgear for your surface processing facilities, all up to 25 kV. Arc Resistant, small footprint, and other specialty designs available.

- Walk-in style, outdoor rated (NEMA 3R), or ruggedized underground designs available

- Available designs with 12 circuits or more

- Ratings up to 25 kV and 3000A

- All major VCB brands available (ABB, Siemens, Eaton, Toshiba, Schneider)

- Modular, fast-custom solutions available (<12-14 weeks)

- Traditional, Arc-Mitigating, and Arc-Resistant designs available

- Air Insulated Switchgear (AIS) designs up to 25 kV and 3000A

- Compact footprint 35 kV Gas Insulated Switchgear (GIS) available

- Specialty switchgear with up to 4000A ampacity

- Short circuit Ratings available up to 50KAIC

Dry-Type Transformers

We build hundreds of MVA of dry-type transformers for underground mining applications every year. We’ve invested in state-of-the-art core steel cutting and coil winding equipment. Our transformers range from 100 KVA up to 10 MVA or more, with voltages up to 25 KV.

- Standard and custom-designed and manufactured dry-type transformers up to 7.5 MVA with voltages up to 25 kV

- Dual primary and secondary voltages available

- Meet highest DOE efficiency standards

- Custom designs manufactured in as few as 8 weeks

- We source oil-filled transformers up to 115 kV and 20 MVA

- IE Dry-type transfers all offer step-lapped, mitred cores with M6 core steels or finer

- Copper windings, VPI on every coil

- 220°C insulation system

- Tested per ANSI C57.12.01; testing capability up to 150KV BIL

E-Houses / PDCs

Whatever you call them - E-houses, MCC buildings, PDCs - we build them. We ship hundreds of custom walk-in electrical enclosures per year into the mining industry, integrating switchgear, distribution panels, MCCs and VFDs, automation and controls, and other electrical contents of your choice, fully tested.

- Customizable walk-in style electrical enclosures

- 100% integration and testing of all power distribution equipment, whether equipment is IE sourced or customer supplied

- State approvals for all 50 states and various international jurisdictions

- Integrated HVAC systems with up to 100T cooling

- Enclosures ranging from 6’ x 6’ to single piece buildings of 20’ x 75’; multi-piece split designs reaching 50’ x 200’ or greater

- Built to International Building Code (IBC) 2015; manufacturing process ensures built to all local codes and approvals

- Blast resistant and other specialty capabilities

Modular / Unit Substations

Our ruggedized modular substations form the backbone of power distribution at mine surfaces. Standard designs available for primary utility, perimeter, pit, portal, and other unit substations. Single skid designs up to 15 MVA. Fixed substations and relay control buildings available for substations exceeding 20MVA.

- Utility substations up to 20 MW on a single skid; designs coordinated with local utilities, including on-skid metering

- Outdoor rated or walk-in style switchgear and control rooms

- Perimeter subs, pit subs, portal subs, and other unit substation designs available

- Modular designs reduce substation lead times from 8-12 months to four months or less

- Utility substations receiving up to 115 kV primary power and 20 MVA in size; relay control buildings for installations over 20 MVA

- Perimeter, pit, and portal subs up to 10 MVA with up to five feeder circuits

- Ruggedized skids for mobile use in the mine; NEMA 3R and other weather protected designs available

- Arc Resistant designs available

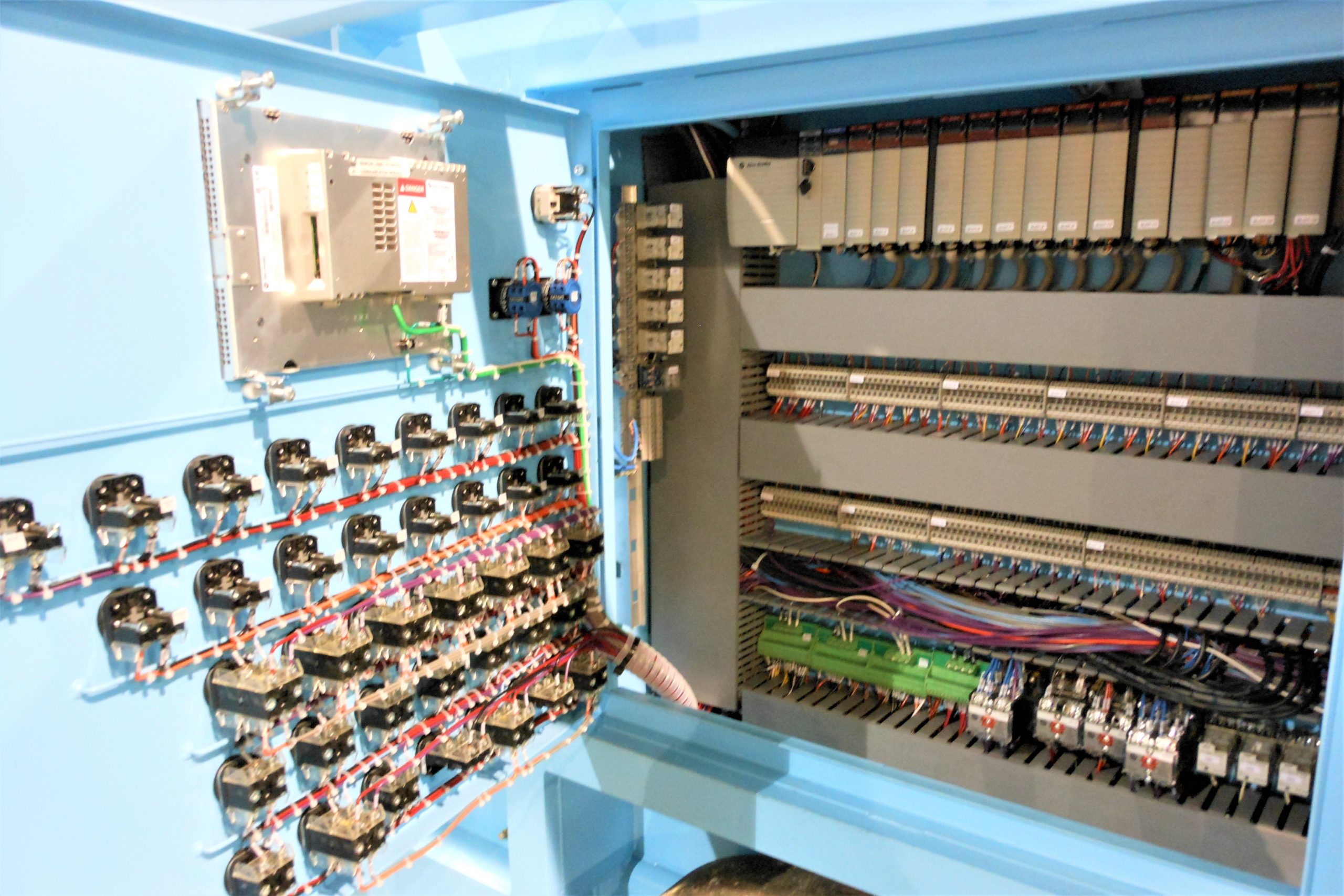

PLCs / Automation

We build UL 508a certified PLC and relay panels in all four factory locations. We quote to specification, or will custom design and develop PLC hardware and programs based on control narratives developed with input from customers. We have a deep automation bench offering full custom programming capabilities.

- Offer design, build, and program capabilities

- Load customer supplied programs, or will collaborate with customer to develop control narratives with customer input to develop custom program.

- Manufacture high volumes of both relay panels and PLC panels

- UL 508a certified panel facilities

- Source and build with Rockwell/Allen-Bradley, Schneider, Siemens, and various other PLC components manufacturers

Field Services / Automation

Commissioning, startup, and troubleshooting services at competitive rates, covering mechanical, electrical, automation, and programming services.

- Turnkey project delivery by IE includes onsite project management, commissioning, and startup

- Mechanical, electrical, automation, and programming services available

- MSHA xxxx certified