IE’s custom dry-type transformers set the standard for quality in North America.

Transformers (Dry-Type and Oil-Filled)

IE’s custom dry-type transformers set the standard for quality in North America, with thousands in service in the mining, utility, and other industrial sectors.

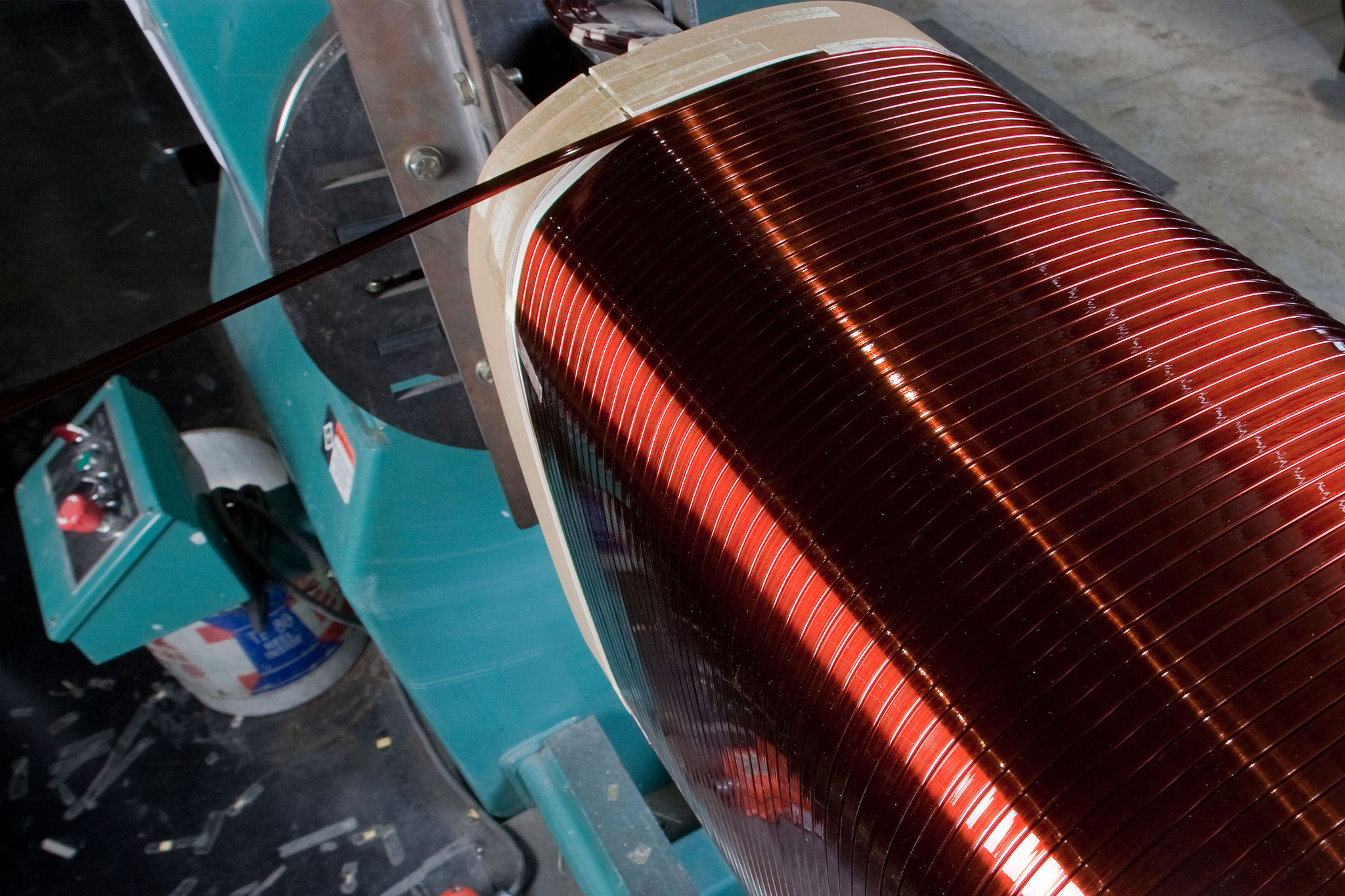

When IE first began manufacturing dry-type transformers in 2006, we invested in state-of-the-art manufacturing and testing equipment. In 2010 we were one of the first manufacturers in North America to purchase a high-performance GEORG core cutting machine, allowing us to build a high efficiency, step-lap, mitre core into every one of our transformers. Further investments in testing and winding allow us to continue to be at the forefront of dry-type transformer technology and productivity.

IE – Engineered by Operators™

Summary Design Elements

- High-efficiency, step-lap mitre core construction is standard on every transformer, for maximum efficiency

- All copper windings, with two-step Vacuum Pressure Impregnation (VPI) on every unit

- Barrel and disc wound designs available

- Optional high voltage epoxy end caps for additional moisture and contaminant protection.

- Standard three-leg and custom five-leg designs available for low profile environments

- Reconfigurable primary for dual feeder voltage capabilities

- Two or more secondary voltages available

- IE designed and manufactured custom enclosures (ventilated and non-ventilated)

Key Performance Specs

- Custom designs from 100 KVA up to 10 MVA

- Primary and secondary voltages up to 25kV; multiple secondary voltages available

- Built to ANSI C57.12.01 standard; all IEEE and ANSI standard met

- UL XXXX designs available