Founded in 1985 in Carbon County, Utah, you could say mining is in our blood. No one does critical infrastructure like IE.

Engineered by Operators ™

For three decades, IE has carefully crafted a practical, street-smart culture by hiring industry experts that bring deep knowledge and experience. We thrive by offering unparalleled service – taking care of one customer at a time. This makes us the “easy button” for which our customers rely to simplify their complex electrical, process, and automation needs.

Collectively, our team has over 300 years of experience working as field operators. This allows us to be more of a partner than vendor. Our goal is to create lasting relationships that is what makes us special.

Lastly, we take pride in the fact that our products are made in the USA. We have grown the business without institutional investors or external sources of capital/debt. Instead, we focus on investments which improve the experience for our customers, employees, and partners.

IE Corp Timeline

Vision & Core Values

We know who we are, what we stand for, and where we are headed.

Our mission is to “Redefine performance standards in our industries, and in so doing, maximize growth for our company, our employees, their families, and our communities”.

Here we unequivocally recognize that the growth we seek for our company and communities can only be achieved as we “raise the bar” in customer performance. We are hungry to do so.

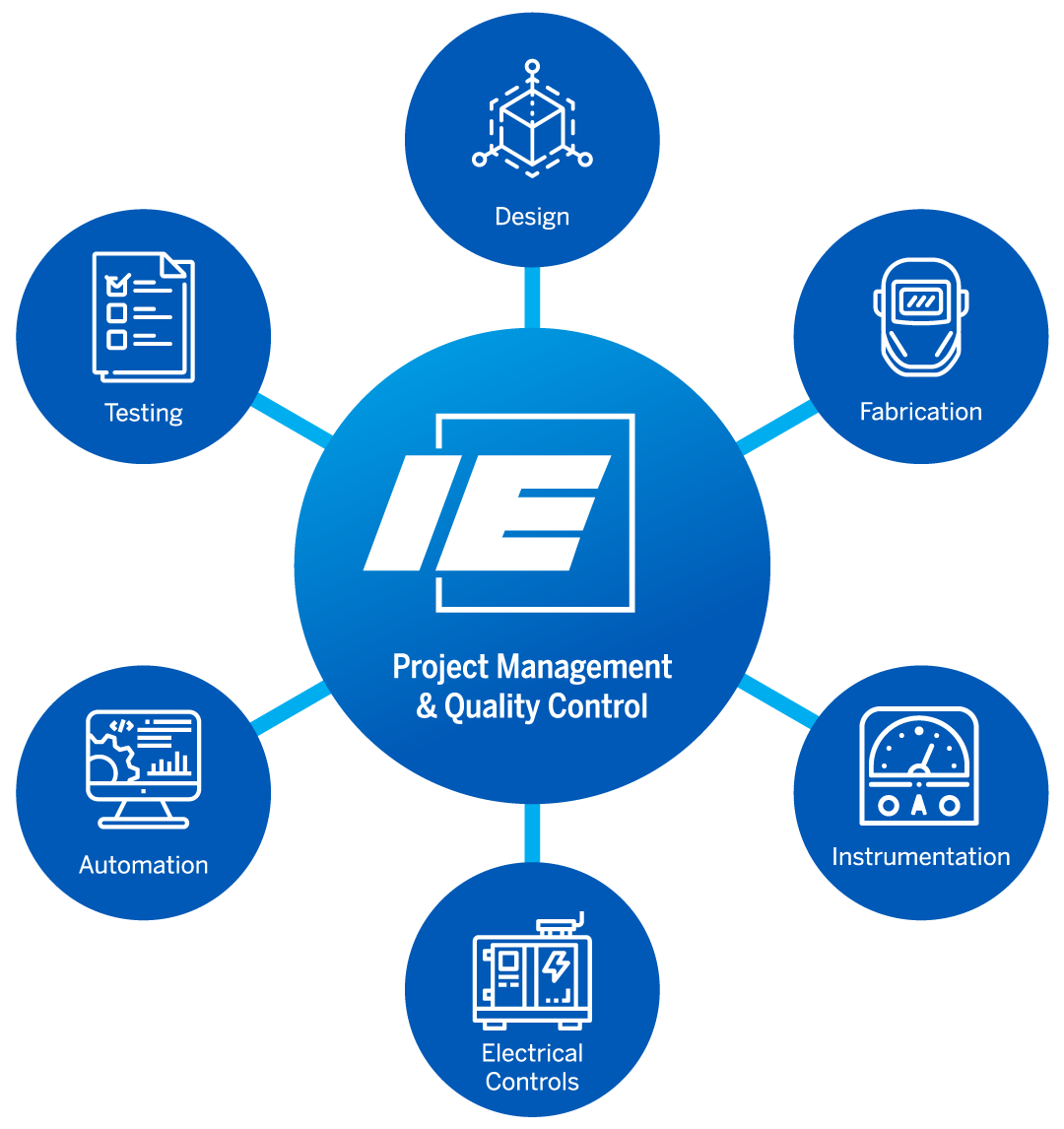

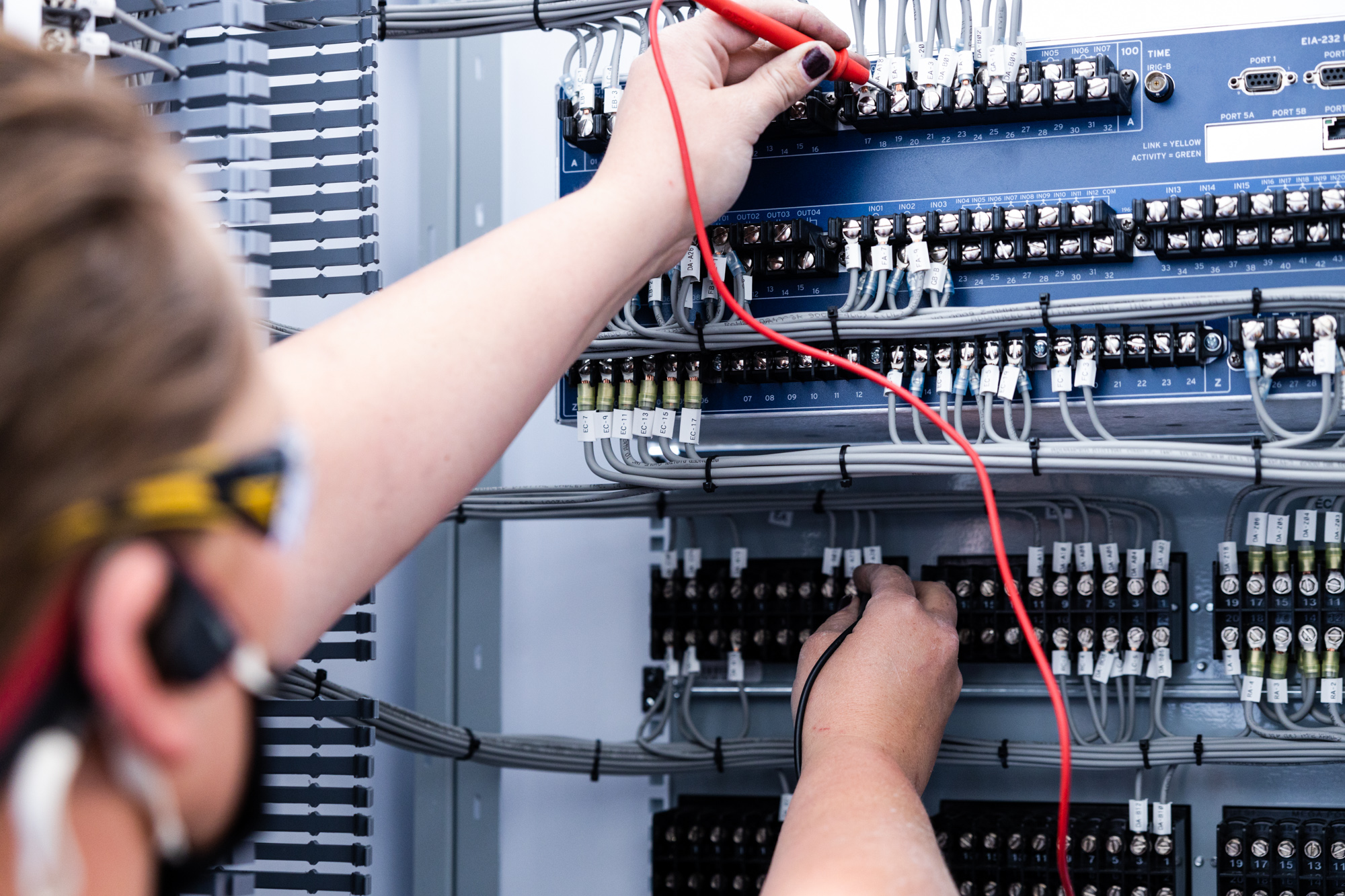

Multi-Discipline Expertise

As operators, we understand the value from combining depth and expertise in specific disciplines with breadth across many. We offer deep capabilities in seven areas:

- Engineering and Design

- Fabrication

- Process & Instrumentation

- Electrical and Controls

- Automation and Programming

- Testing

- Project Management

This allows us to provide smart, practical, turnkey solutions, making it easy for you.

An Operator’s View

Our founder spent 15 years in the mining sector prior to founding IE. With this background, he has focused on instilling a different kind of value. Our solutions and service must be available 24-7. Overengineering doesn’t save you money. Nor does skimping. Our team will help you get it “just right”, based on real-world experience and a practical approach.

We will show you this from day one. Our mining team will match you with an industry expert who can talk shop.

Fast & Flexible

Custom doesn’t have to mean slow. Our applications and operations team, comprised of industry experts, leverages their experience and deep library of project activity to develop solutions in tight time periods. Need to make changes? We can accommodate – we understand that not every project has a clean set of drawings on day one.

Our team of experts is also pragmatic – we will be honest with you and let you know when it is time to make a decision in order to keep your critical schedule.

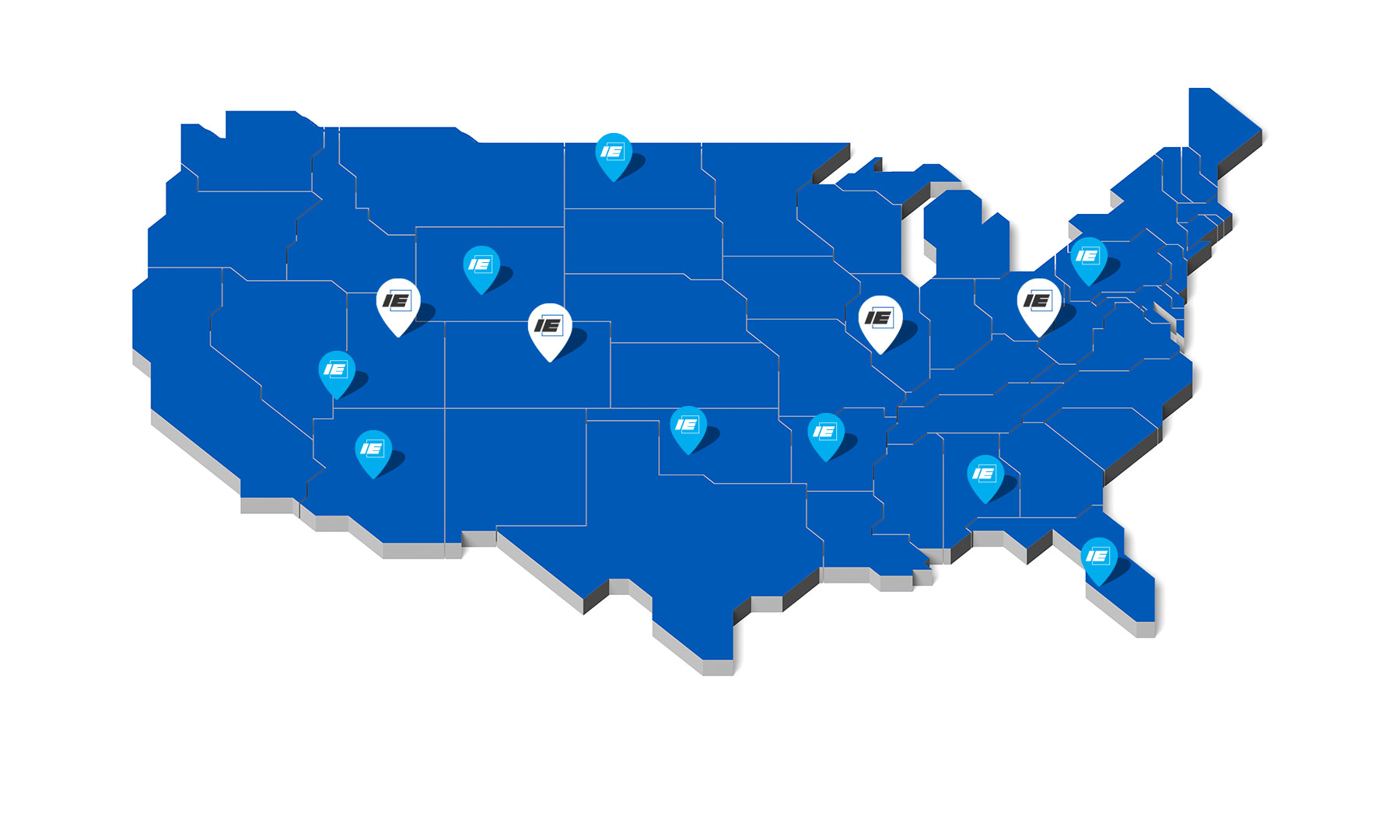

National Support & Footprint

Our four factories and seven service locations are built to provide service and expertise at a regional level. Our factories are spread from the East to the West, with local manufacturing in:

- Price, UT (HQ)

- South Point, OH

- Centralia, IL (near St. Louis, MO)

- Denver, CO

- Scottsdale, AZ

- Pittsburgh, PA

Our goal is to be the easy button, making it easy for you to get local help, attend Factory Acceptance Tests (no charge), and minimize freight expenses while simplifying shipping logistics.

National Support & Footprint

Our four factories and seven service locations are built to provide service and expertise at a regional level. Our factories are spread from the East to the West, with local manufacturing in:

- Price, UT (HQ)

- South Point, OH

- Centralia, IL (near St. Louis, MO)

- Denver, CO

- Scottsdale, AZ

- Pittsburgh, PA

Our goal is to be the easy button, making it easy for you to get local help, attend Factory Acceptance Tests (no charge), and minimize freight expenses while simplifying shipping logistics.

National Support & Footprint